3D CHAIN MAIL ASSEMBLY

A behind the scene video of the fabrication and construction process of the 3D Chain Mail Assembly project from the Swinburne University of Technology for The International Association for Shell and Spatial Structures (IASS) Expo 2023 at RMIT Design Hub, Melbourne, Australia.

More information and update on the project coming soon...

More information and update on the project coming soon...

MODULAR STEREOTOMY

Abstract taken from the published article https://doi.org/10.1007/s00004-021-00577-6:

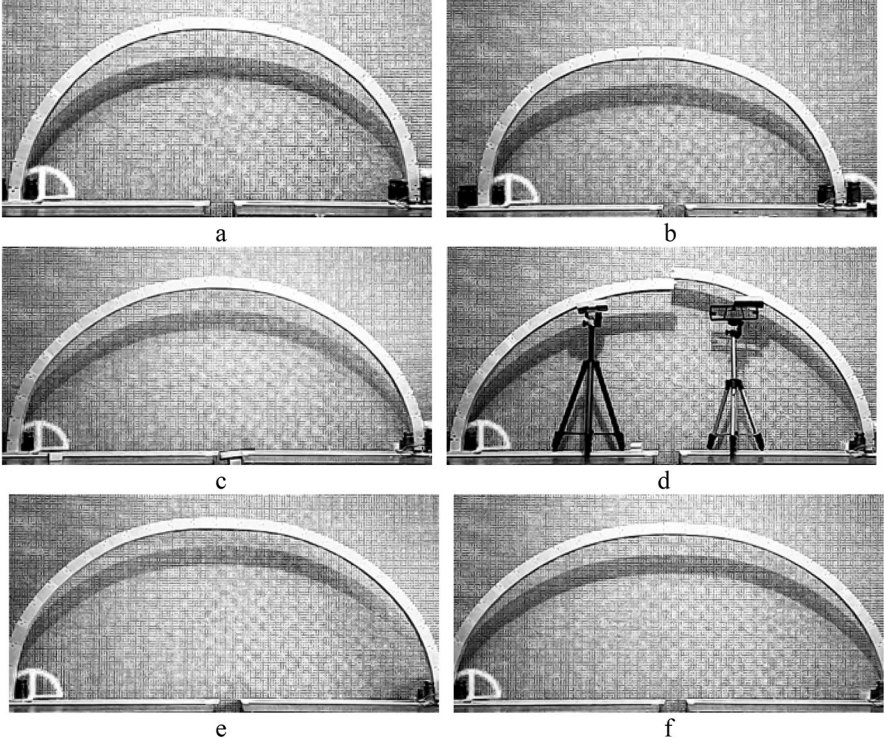

In the last decade, research interest in digital stereotomy has been renewed, with efciency as a popular objective. However, along with a mainstream focus on full customization, comes a paradox of efficient design yet inefcient fabrication. Provoked by this situation, the potential of modular stereotomy is explored here. By utilizing a parametric design approach and rapid additive prototyping method, sequential experiments were executed to test seventy variations of units. As a result, a clear workfow and an optimized design were generated and used to form a modular stereotomy construction. Finally, efciency was achieved from three standpoints: main material efciency through complete modularity, supporting material efciency through total elimination of shims and up to 91% reduction in falsework, and material use-value maximization through an easy assembly of form and a selection of up to six diferent constructional strategies to build arches with similar shape and volume.

In the last decade, research interest in digital stereotomy has been renewed, with efciency as a popular objective. However, along with a mainstream focus on full customization, comes a paradox of efficient design yet inefcient fabrication. Provoked by this situation, the potential of modular stereotomy is explored here. By utilizing a parametric design approach and rapid additive prototyping method, sequential experiments were executed to test seventy variations of units. As a result, a clear workfow and an optimized design were generated and used to form a modular stereotomy construction. Finally, efciency was achieved from three standpoints: main material efciency through complete modularity, supporting material efciency through total elimination of shims and up to 91% reduction in falsework, and material use-value maximization through an easy assembly of form and a selection of up to six diferent constructional strategies to build arches with similar shape and volume.

WEAVING CONCRETE BLOCK

Abstract taken from the published article https://doi.org/10.22452/jdbe.vol19no3.1

This paper presents creative geometry research focusingon computational design explorationto improvetheeco-performance of concrete blocks used as a building material.To provide a positiveeco-performance, an optimized concrete block was designed to be more efficientthan a conventional concrete blockwith respect tothe materialsusedand the space occupied during storageand transport. The results prove that the form iscost-effective and that the environmentalimpactcaused by associatedproduction and distributionprocesseswould be comparatively reduced.Computationalresearch based on parametric design thinkingenabledthe relationship between form properties as selected design parameters to beevaluated, withthe aim ofensuringthat efficiency doesnot compromise technical requirementsand that the overall functional roleof the concrete blockis appropriate when usedas a constituent material innonstructuralwall construction. Volumetric-based measurements wereemployedusingRhinocerosmodelingsoftware with a Grasshopper plug-into assess the eco-performance of the concrete block based on selected indicators. The resultsshow that the folded S-shape concrete block with awidth of 40 mm consumesonly 43% of the main material and 14% of the auxiliary material relative to aconventional concrete blockwith a width of 100 mm.When arranged horizontally,a standard container can hold60% more of the optimized concrete block units comparedto conventional ones. Additionalfindings were also made thatsuggestfuture research potential,including use of the concrete blocks as building elements inpassive design strategies.

This paper presents creative geometry research focusingon computational design explorationto improvetheeco-performance of concrete blocks used as a building material.To provide a positiveeco-performance, an optimized concrete block was designed to be more efficientthan a conventional concrete blockwith respect tothe materialsusedand the space occupied during storageand transport. The results prove that the form iscost-effective and that the environmentalimpactcaused by associatedproduction and distributionprocesseswould be comparatively reduced.Computationalresearch based on parametric design thinkingenabledthe relationship between form properties as selected design parameters to beevaluated, withthe aim ofensuringthat efficiency doesnot compromise technical requirementsand that the overall functional roleof the concrete blockis appropriate when usedas a constituent material innonstructuralwall construction. Volumetric-based measurements wereemployedusingRhinocerosmodelingsoftware with a Grasshopper plug-into assess the eco-performance of the concrete block based on selected indicators. The resultsshow that the folded S-shape concrete block with awidth of 40 mm consumesonly 43% of the main material and 14% of the auxiliary material relative to aconventional concrete blockwith a width of 100 mm.When arranged horizontally,a standard container can hold60% more of the optimized concrete block units comparedto conventional ones. Additionalfindings were also made thatsuggestfuture research potential,including use of the concrete blocks as building elements inpassive design strategies.

CRAFTING INTELLIGENCE #2

PROJECT Fabric Structure

DESCRIPTION

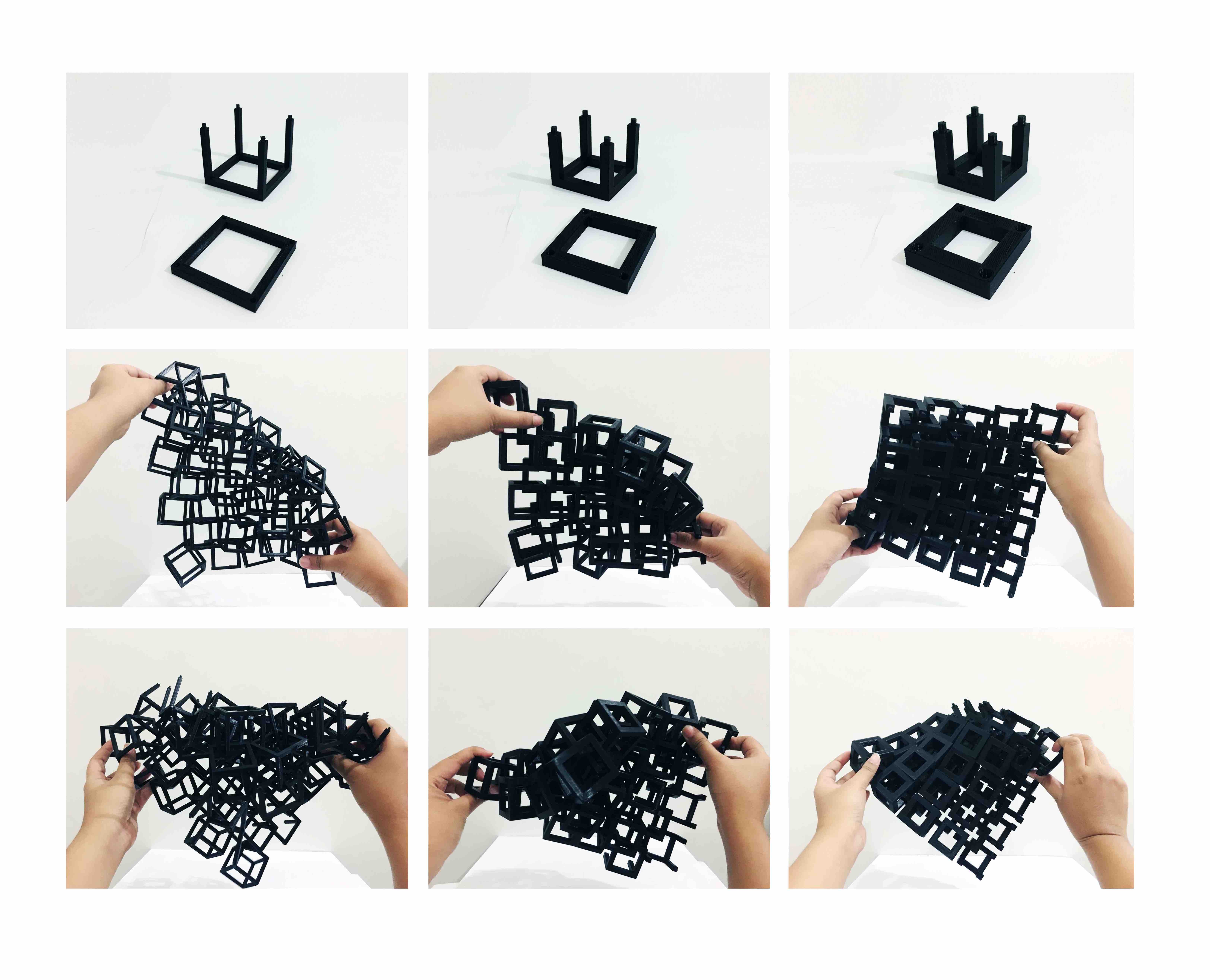

Crafting Intelligence #2 is a continuation of the interlocking fabric structure study conducted through the Crafting Intelligence #1's project. This part is focused on the investigation of the solid-to-void ratio's impact on the material system's flexibility and stability.

DESCRIPTION

Crafting Intelligence #2 is a continuation of the interlocking fabric structure study conducted through the Crafting Intelligence #1's project. This part is focused on the investigation of the solid-to-void ratio's impact on the material system's flexibility and stability.

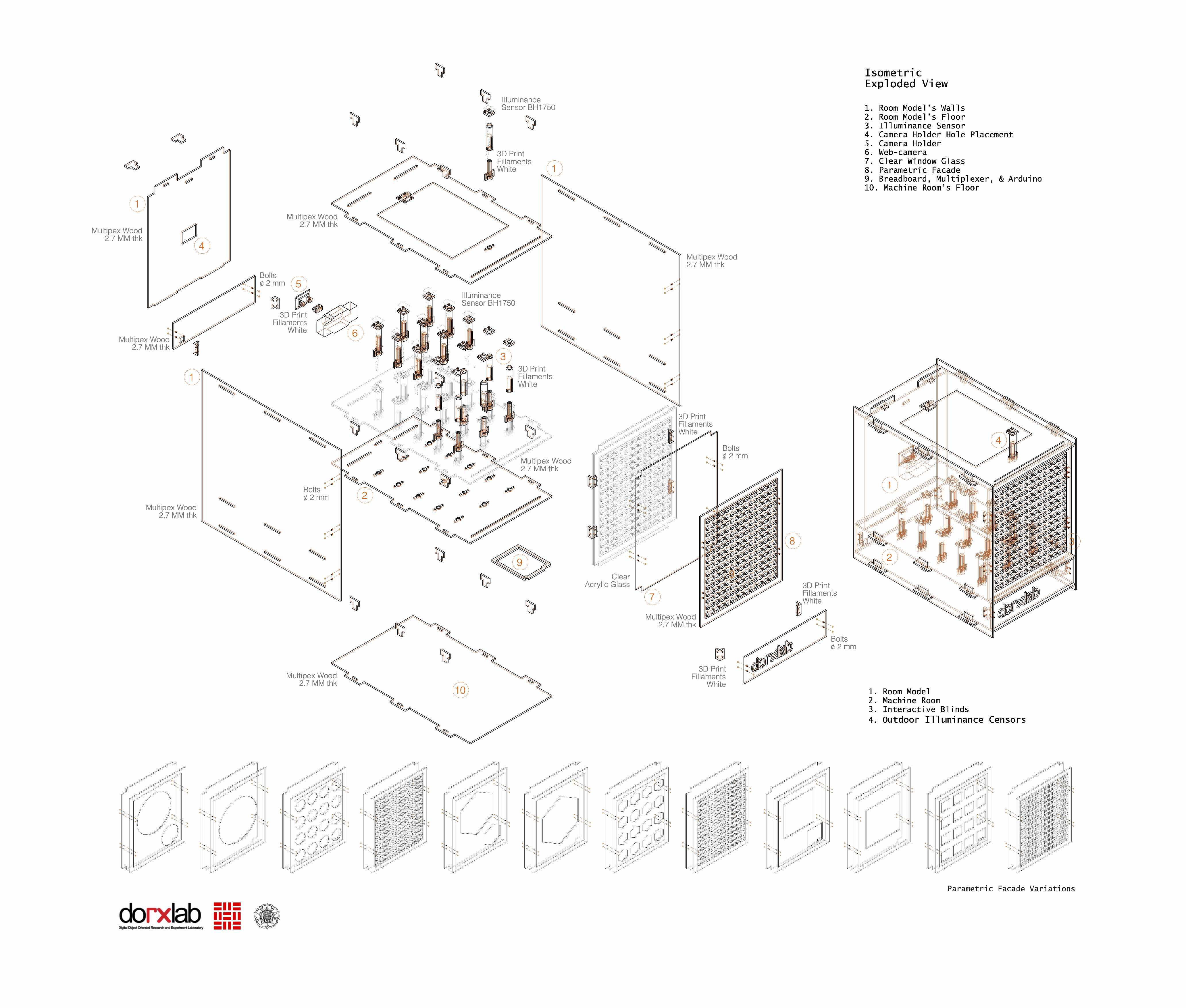

PARAMETRIC FAÇADE

PROJECT Parametric Façade | Universitas Gadjah Mada

COLLABORATORS Dr. Eng Agus Hariyadi, Annisa Cinderakasih

DESCRIPTION

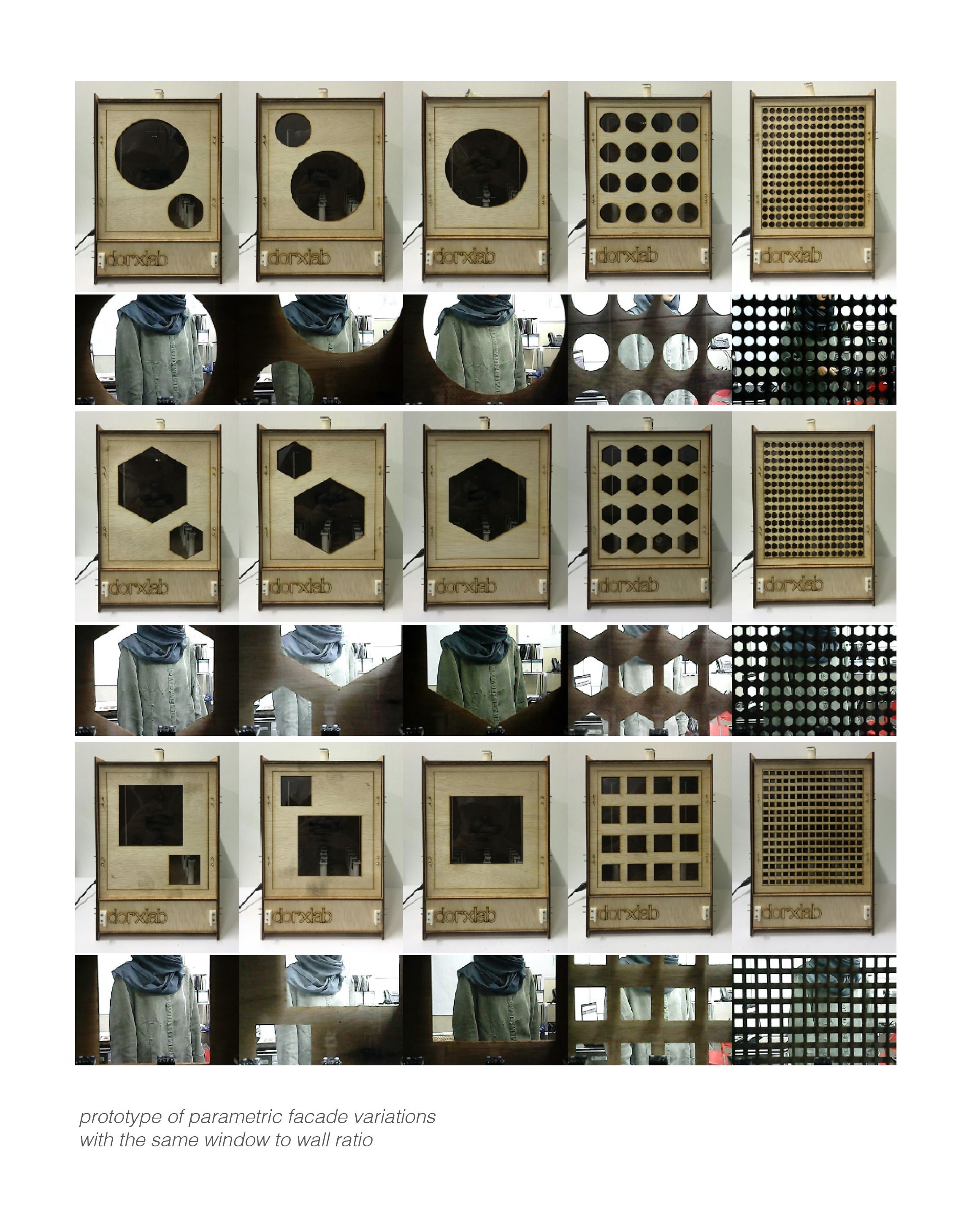

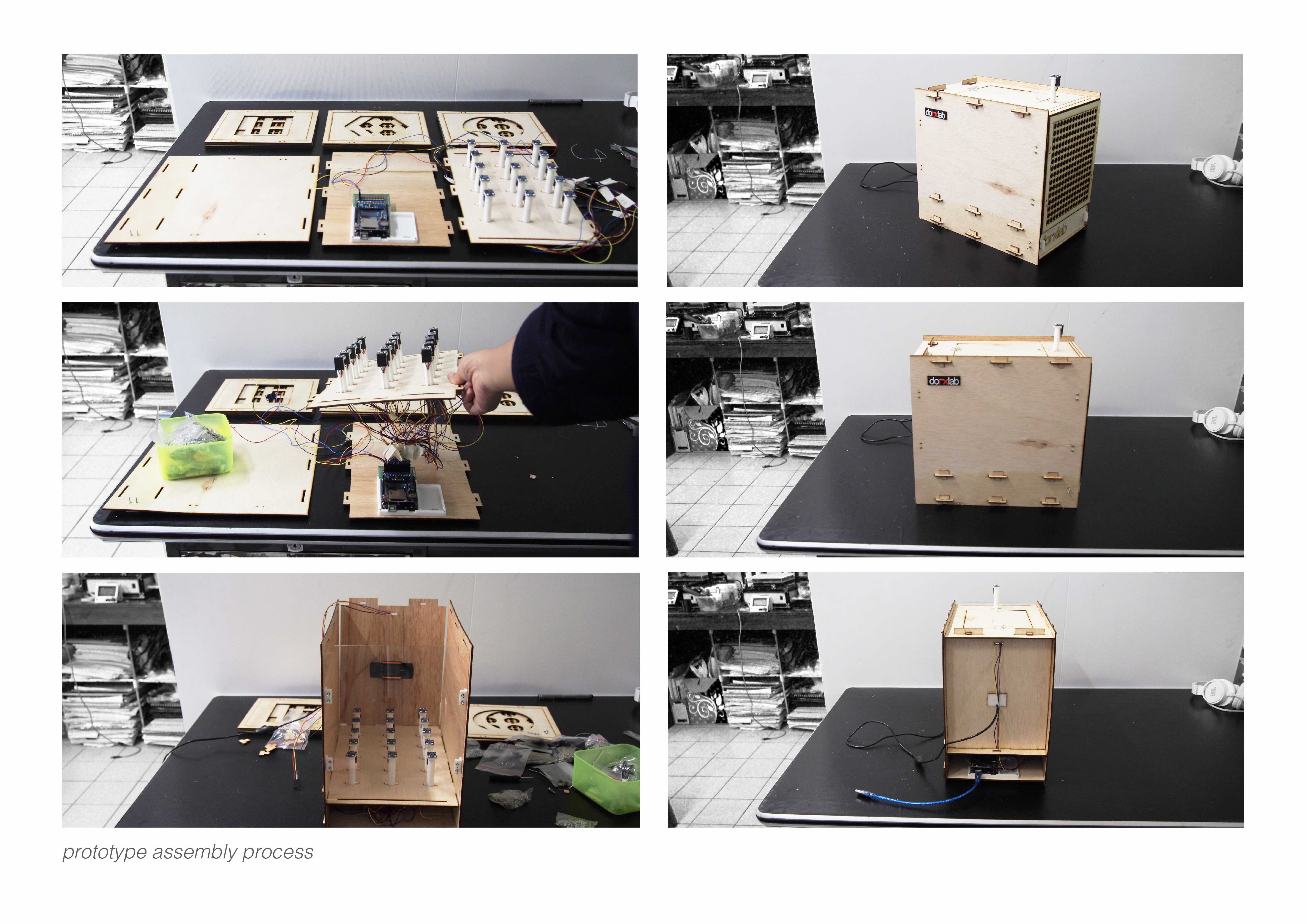

The Parametric Façade is a parametric facade prototype in the form of a 1: 100 scale room equipped with glass windows and a double skin façade. This double-skin façade is designed with a parametric design method with the aim of exploring creative designs to produce an extensive and almost unlimited variety of building skin designs, in order to answer the unrest of the general public and architects in particular regarding building envelope rules that are considered too limiting.

In this prototype, the building envelope rule that is used as a reference is the Windows to Wall Ratio (WWR) limitation of 40%, with the resulting variation limited to 15 design variations. The 15 design variations used at this stage are grouped into three design groups based on the selected initial geomaterial/basic shape, namely (1) circle, (2) triangle, and (3) hexagon. Then, within each of these geometry groups, five alternatives were developed, all of which have the same void: solid proportion, namely 4: 6. The five variations are differentiated based on the level of distribution/evenness of the openings on the facade surface using a grid system: (1 ) 1 x 1, (2) 1 x 2, (3) 4 x 4, (4) 9 x 9, and (5) 15 x 15.

COLLABORATORS Dr. Eng Agus Hariyadi, Annisa Cinderakasih

DESCRIPTION

The Parametric Façade is a parametric facade prototype in the form of a 1: 100 scale room equipped with glass windows and a double skin façade. This double-skin façade is designed with a parametric design method with the aim of exploring creative designs to produce an extensive and almost unlimited variety of building skin designs, in order to answer the unrest of the general public and architects in particular regarding building envelope rules that are considered too limiting.

In this prototype, the building envelope rule that is used as a reference is the Windows to Wall Ratio (WWR) limitation of 40%, with the resulting variation limited to 15 design variations. The 15 design variations used at this stage are grouped into three design groups based on the selected initial geomaterial/basic shape, namely (1) circle, (2) triangle, and (3) hexagon. Then, within each of these geometry groups, five alternatives were developed, all of which have the same void: solid proportion, namely 4: 6. The five variations are differentiated based on the level of distribution/evenness of the openings on the facade surface using a grid system: (1 ) 1 x 1, (2) 1 x 2, (3) 4 x 4, (4) 9 x 9, and (5) 15 x 15.